High Density MCC

Construction

Application

Introduction

Electrical Energy should be distributed safe and controlled for human safety, most of the industrial companies defined for the operation of their electrical switch gears three lines of defense to avoid accidents by the hazardous potential of electrical energy which are:

Third line: Regulation: using special cloth and following the electrical safety rules

Second Line: Limitation: additional mechanical measures

First Line: Prevention: measures of encapsulation of parts which are alive.

The heart of switchboards in draw‐out‐technology is its contacting‐device, which is responsible to take the energy from the bus‐bar‐system. Prevention means that the contacting device, the vertical bus‐section and the outgoing‐plug form up a hermetic encapsulation which means an arc‐fault‐ free‐zone. Prevention also means the technical advantages of the pressure‐contacts

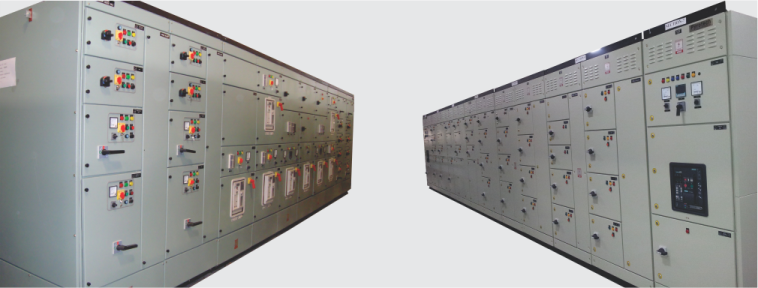

Motor Control Center

Features

- Our MCC are made in fully compartmentalized modular design cabinet system designed for powering and controlling motors.

- As per standards IS 8623 & IEC 60439

- Our MCC are two types (1) Fixed type MCC (2) Drawout MCC Provision of single front and double front

Lighting Panel

Features

- Robust Construction

- Corrosion Resistant

- Superior Quality

- Durable Life

- Meeting International Standard

- Modular Design

- Approved by NTPC/ BHEL /MECON /EL /TCS & all major OEMS